What is RTO (Regenerative Thermal Oxidizer)

RTO(Regenerative Thermal Oxidizer)is a treatment equipment that uses catalytic oxidation combustion technology to efficiently purify organic waste gas. The full name is “RTO regenerative thermal oxidation furnace equipment”. Compared with traditional catalytic combustion and direct-fired TO furnaces, it has the characteristics of high thermal efficiency (≥95%), low operating costs, and can handle high-volume and high-concentration exhaust gases. When the concentration is slightly higher, it can also perform secondary waste heat recovery. , greatly reducing production and operating costs.

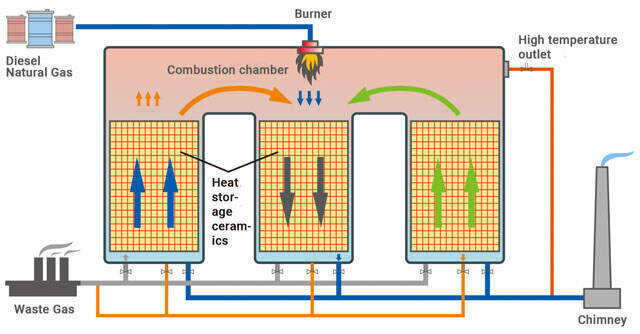

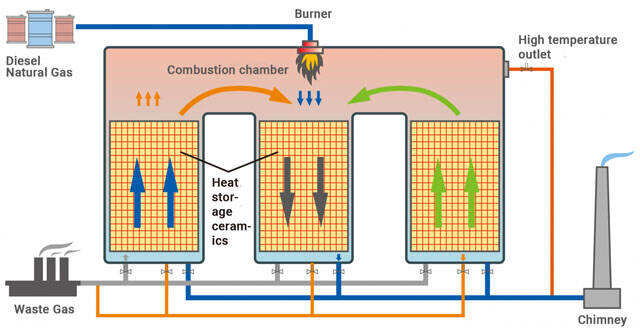

The operating principle of RTO (Regenerative Thermal Oxidizer):

The principle of RTO (Regenerative Thermal Oxidizer) is to heat the organic waste gas to above 760 degrees Celsius, so that the VOC in the waste gas is oxidized and decomposed into carbon dioxide and water. The high-temperature gas generated by oxidation flows through a special ceramic regenerator, which makes the ceramic body heat up and “reserve heat”, which is used to preheat the organic waste gas that enters later. The ceramic regenerator should be divided into two (including two) or more areas or chambers, and each regenerator undergoes the procedures of heat storage-radiation-cleaning in turn, repeating and working continuously. After pyrolysis, the regenerator should immediately introduce an appropriate amount of clean gas. Before entering the exhaust gas treatment system or directly discharging, each chamber should be purged to ensure the removal rate of VOC.

The application of RTO (Regenerative Thermal Oxidizer):

RTO(Regenerative Thermal Oxidizer) has a wide range of applications, including: chemical industry, pharmaceutical industry, paint and coating production, spray painting industry, petroleum industry, chemical industry, semiconductor industry, automobile industry and coating coatings and other industries.

BIOETP provide service for ETP/STP

designing, equipment manufacturing, plant installation, operation

training and maintenance service. also provide solutions and equipments

for almost all kinds of sludge dewatering treatment. also provide smell

control solutions and smell control plant and related equipmentsfor APIs

industry and feed processing industry.

So,

if you have any ETP/STP , sludge dewatering , smell control requirement

aroused, please feel free to contact BIOETP. You can find our contact

on BIOETP official website www.bioetp.com.