The rotary drum screen is used for municipal sewage and industrial wastewater treatment plants.It allows combination of screening, washing, transportation and dewatering in single unit.

As a new type of equipment for wastewater treatment,bar screen is more and more used by major enterprises,but the types of bar screen are not the same.The classification of bar screen also has different methods.According to the size of the bar screen,the bar screens are divided into three categories:coarse bar screen,medium bar screen and fine bar screen.According to the slag cleaning method of the bar screen,there are three types:manual bar screen,mechanical bar screen and hydraulic cleaning bar screen.According to the different structural characteristics of the bar screen,it can be divided into various forms such as grasping rake bar screen,arc bar screen,rotary bar screen,drum bar screen,tooth rake bar screen and stepped bar screen.

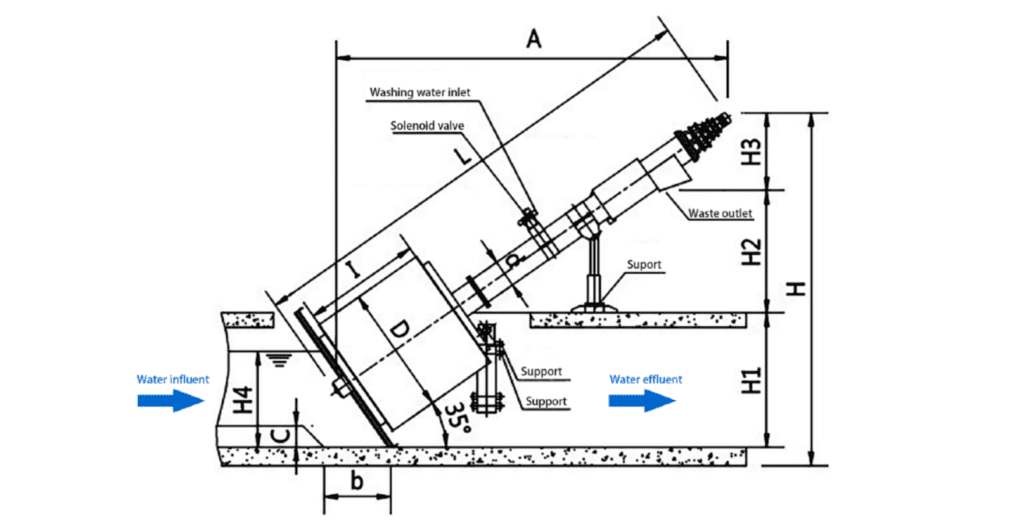

Working Principle Of rotary drum screen:

The equipment of the rotray drum screen is installed in the water channel at 35° to the horizontal plane.The sewage flows into the drum from the end of the drum,the water flows out through the grid gap of the bar screen,and the solid waste is filtered in the bar screen basket.The cleaning arm cleans the gaps of the bar screen when it moves in a circular motion,and the rake teeth extend into the bar screen to take out the solids.When the cleaning arm is at a high point, the rubbish is removed from the rake teeth by washing with water and the action of the slag baffle,and fall into the screw conveying bucket of the garbage collection device.During the conveying process,it is dehydrated by the action of changing the pitch,squeezed dry in the upper end compression area,and the squeezed water is returned to the water channel,and the garbage is sent to the container or subsequent equipment,process again.

Bioetp’s rotary drum screen elements can either be wedge wire spaced at 0.5-6mm, or 106mm perforated drums. Depending on the aperture size selected and the screen diameter, the throughput can be individually adjusted to specific site requirements.

Being a solid liquid separation solution provider, Bioetp is with rich experience in design and manufacturing the wastewater treatment machine. More important, Bioetp is able to provide overall solution for separation and conveying with the rich product line and strong fabrication and assembly capabilities.

So,if you have any industrial solid liquid separation requirement aroused, please feel free to contact Bioetp. You can find our contact on Bioetp official website www.bioetp.com.