Before at,the sludge dewatering machine includes:multi disc screw press,belt filter press,decanter centrifuge and more.but today we just taking about the multi disc screw press.

Information of Multi Disc Screw Press

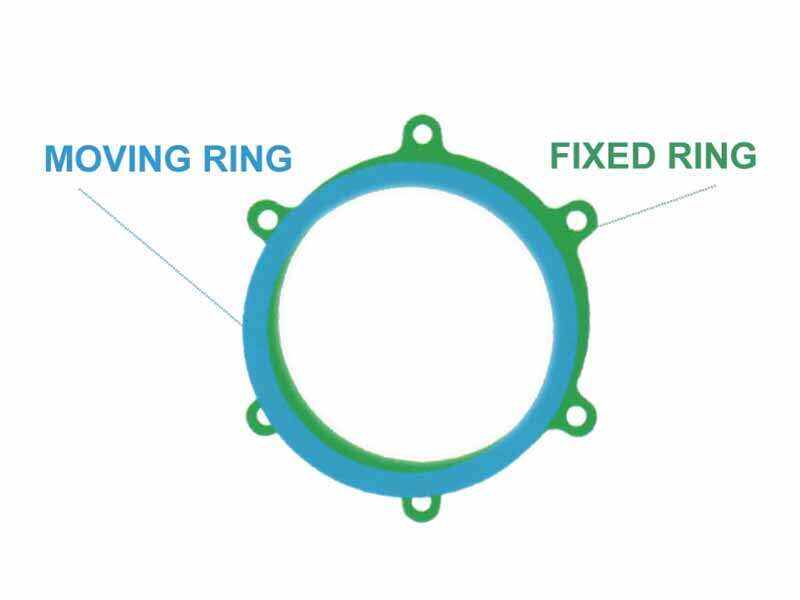

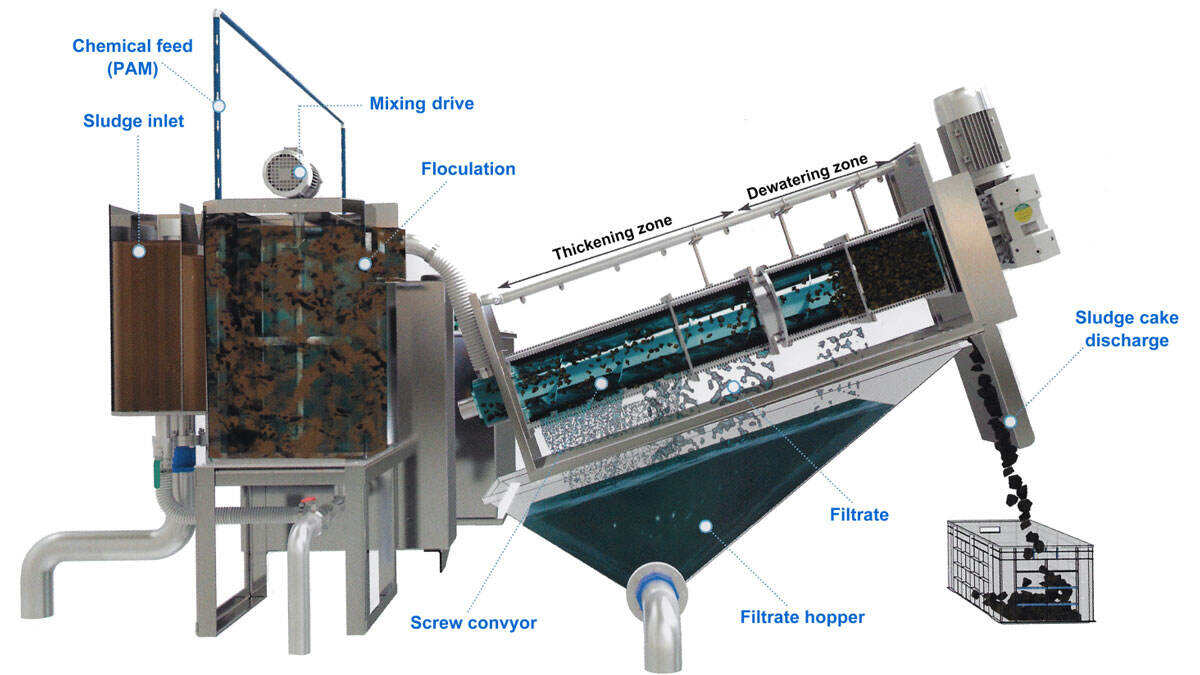

The multi disc screw press sludge dewatering process is mainly composed of two parts: metering dosing and the multi disc screw press body. The metering and dosing part is composed of a metering tank, a flocculation mixing tank and a dosing pump. The main part of the stacked screw is composed of a fixed ring and a floating ring stacked on each other, and a screw thrust shaft penetrates through it. It is divided into a concentration zone and a dehydration zone. The filter gap between the fixed ring and the moving ring and the pitch of the screw shaft gradually decrease from the concentration zone to the dehydration zone.

Multi Disc Screw Press Working principle

The main principle of the multi disc screw sludge dewatering machine is to use the adjustable gap between the fixed ring and the moving ring to intercept the solid phase material. When the sludge enters the filter body, the relative movement of the fixed ring and the floating ring is used to make the filtrate quickly discharged through the gap between the laminated sheets, and the sludge moves to the dewatering section. When the sludge enters the dewatering section, the filter cavity The space is constantly shrinking, the internal pressure of the sludge continues to increase, coupled with the back pressure of the back pressure plate at the mud outlet, it reaches the dehydrated state, and the dry mud is continuously discharged out of the machine. By adjusting the speed of the screw shaft and the gap of the pressure of the back pressure plate, the sludge treatment capacity and the sludge moisture content can be effectively adjusted. Under the action of the rotation of the screw shaft, the movable plate is constantly staggered relative to the fixed plate, thereby realizing a continuous self-cleaning process and avoiding the common blocking problem of traditional dehydrators.

Multi Disc Screw Press Process Flow

The back end of the sludge thickening tank adopts the screw-stacking desludge method, the processing capacity is 10m³/h, and the concentration of organic flocculant is 20mg/L. During the operation of the equipment, the water from the screw stacker is pumped to the sewage recovery tank to settle, and the dehydrated sludge is packed and stored in an impermeable woven bag, which realizes the concentration and dehydration of the sludge discharged in the sewage treatment process. To avoid the vicious circle of sludge in the system.

Sludge Dewatering Effect and analysis

During the test, sampling and testing were performed in the incoming liquid tank, water outlet and mud outlet of the equipment. The test object is a petrochemical plant. The test results show that when the moisture content of the sludge removed from the sludge thickening tank is between 95.8% and 96.7%, the moisture content of the mud cake obtained is 70.3% after being concentrated and thickened by the spiral dewatering machine. Between ~77.6%, the volume of sludge has been reduced by more than 85%. In addition, the content of suspended solids in the concentrated sewage is below 20.5mg/L, and the content of oily substances in the sludge is between 18.2% and 20.4%. The stacked screw-type oily sludge thickening and dewatering device can remove the dry sludge after a few minutes of operation, and the on-site water outlet sampling is clear. The statistics of various indicators in the field test are as follows:

| Unconcentrated sludge before thickening | Thickened and thickened sludge | Sewage after thickening | |||

| Water content (%) | Oil content (%) | Water content (%) | Oil content (mg/L) | Oil content (mg/L) | Suspended solids (mg/L) |

| 96.7 | 0.15 | 70.3 | 19.5 | 15.4 | 20.5 |

| 95.8 | 0.09 | 72.4 | 18.9 | 14.7 | 19.8 |

| 96.4 | 0.28 | 74.6 | 18.2 | 15.2 | 20.3 |

| 96.5 | 0.13 | 73.3 | 20.4 | 15.5 | 19.6 |

And we also compared the multi disc screw press with several other sludge dewatering equipment:

| Compare items | Multi Disc Screw Press | Belt Filter Press | Decanter Centrifuge |

| Dehydration way | Moving ring stacked spiral dewatering | Gravity + Shear Dewatering | Centrifugal dewatering |

| Dewatering of low-concentration sludge | Yes | No | Yes |

| Sludge thickening tank | Unnecessary | Need | Need |

| Sludge storage tank | Unnecessary | Need | Need |

| Energy used | Very few | Big | Big |

| Washing water consumption | Very few | Very large | Small |

| Running noise, vibration | Small | Big | Big |

| Sludge viscosity requirements | Low demand | High standard | Middle |

| Flocculant | Use | Use | Use |

| Mud cake moisture content | <80% | >80% | >80% |

| Sludge treatment rate | >95% | 90%~95% | 90%~95% |

| Unmanned continuous operation for 24 hours | Yes | No | Yes |

Summary

(1) The Muti disc screw press sludge dewatering process has simple structure design, small area, low daily maintenance cost, and good economic, environmental and social benefits.

(2) The actual operation of the site shows that the process is stable and effective. The water content of the sludge from the sludge dewatering machine can be controlled at 70% to 80%. The sludge dewatering machine is used in conjunction with the sewage treatment system to achieve a good effect on the sludge.

(3) This process overcomes the shortcomings of belt filter press and decanter centrifuge, such as easy clogging and high power consumption, and greatly meets the requirements of harmlessness, reduction and resource treatment of sludge.

Being a solid liquid separation solution provider, BIOETP is with rich experience in design and manufacturing the dewatering screw press machine. More important, BIOETP is able to provide overall solution for separation and conveying with the rich product line and strong fabrication and assembly capabilities.

So,if you have any industrial solid liquid separation requirement aroused, please feel free to contact BIOETP. You can find our contact on BIOETP official website www.bioetp.com.