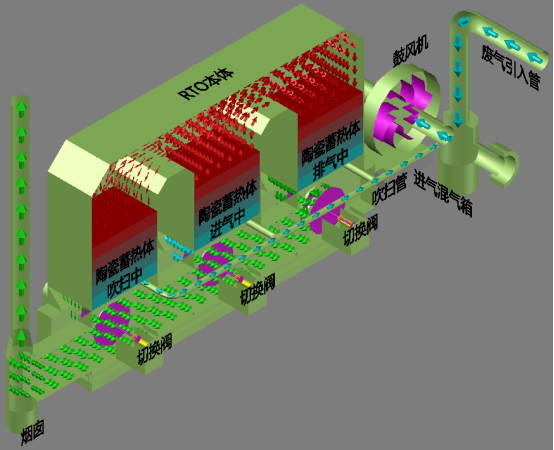

| Components | Functions |

| Upper chamber | It provides time for the oxidation of organic matter, and also has the function of heat storage and heat release. |

| Lower chamber | Bear the load of the upper chamber, control the flow direction of the exhaust gas and flow out of the regenerator. |

| Burning system | Provide heat for the temperature rise of the system startup process and the heat balance of the operation process. |

| Blower | Provide sufficient power for the gas to overcome system resistance |

| Overtemperature relief device | Mix high-temperature gas with low-temperature gas to prevent the high-temperature gas from softening the air duct and scalding the insulation cotton |

| Intake device | Dilute high-concentration organic waste gas and filter tiny particles in the waste gas |

| Chimney | Since the treatment efficiency cannot reach 100%, the treated waste gas must be led to high altitude |

| Flow(Nm3/h) | Regenerative consumption(m3) | Area(m2) | Weight(t) | Power(kw) |

| 5000 | 5 | 40 | 20 | 30 |

| 10000 | 10 | 46 | 28 | 37 |

| 15000 | 15 | 54 | 36 | 55 |

| 20000 | 20 | 59 | 44 | 75 |

| 25000 | 25 | 65 | 51 | 90 |

| 30000 | 30 | 71 | 59 | 110 |

| 35000 | 35 | 78 | 68 | 132 |

| 40000 | 40 | 83 | 73 | 160 |

| 50000 | 50 | 93 | 96 | 200 |

| 60000 | 60 | 104 | 111 | 220 |

| 70000 | 70 | 114 | 126 | 260 |

The BIO Series VOC treatment system combines adsorption + desorption + catalytic oxidation system to destroy 98% of benzene, esters,

The BIO Series GMP Adsorption System is engineered for Pharmaceutical VOC Adsorber, featuring "medical-grade carbon+hot N₂ regeneration" to achieve 99.5%

The BIO Series Lab Adsorber (Activated Carbon Adsorption) is designed for research facilities, featuring "high-iodine carbon+HEPA" technology to remove 99%

Fill out the form below, and we will be in touch shortly.