| ITEM NAME | QY-MD200 | QY-MD270 | QY-MD340 |

|---|---|---|---|

| Service area (m2) | 0.125-0.5 | 0.1875-0.75 | 0.325-1.3 |

| Design air flow (m3/h) | 1-4 | 1.5-6 | 2.5-10 |

| Optimum air flow (m3/h) | 2 | 3 | 5 |

| Maximum air flow (m3/h) | 6 | 9 | 15 |

| Oxygen transfer efficiency (%) | 27-38 | ||

| Working temperature (℃) | 0-80 | ||

| Connector thread (NPT) | 3/4 | ||

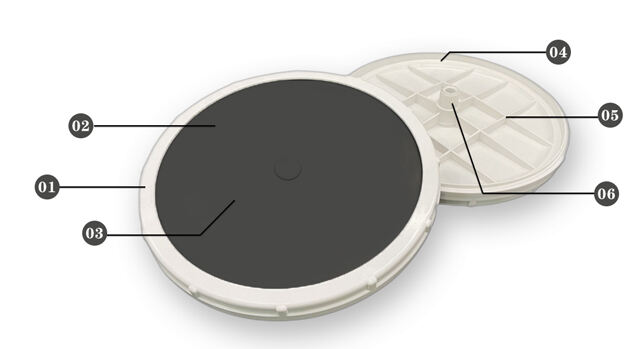

| Membrane thickness (mm) | 2 | ||

| Hole quantity (pcs) | 4400 | 6600 | 11440 |

| Punch size (mm) | 1 | ||

| Bubble size (mm) | 1-2 | ||

| Product diameter (mm) | 228 | 268 | 346 |

| Effective diameter (mm) | 184 | 229 | 295 |

The BIO Series VOC treatment system combines adsorption + desorption + catalytic oxidation system to destroy 98% of benzene, esters,

The BIO Series GMP Adsorption System is engineered for Pharmaceutical VOC Adsorber, featuring "medical-grade carbon+hot N₂ regeneration" to achieve 99.5%

Fill out the form below, and we will be in touch shortly.