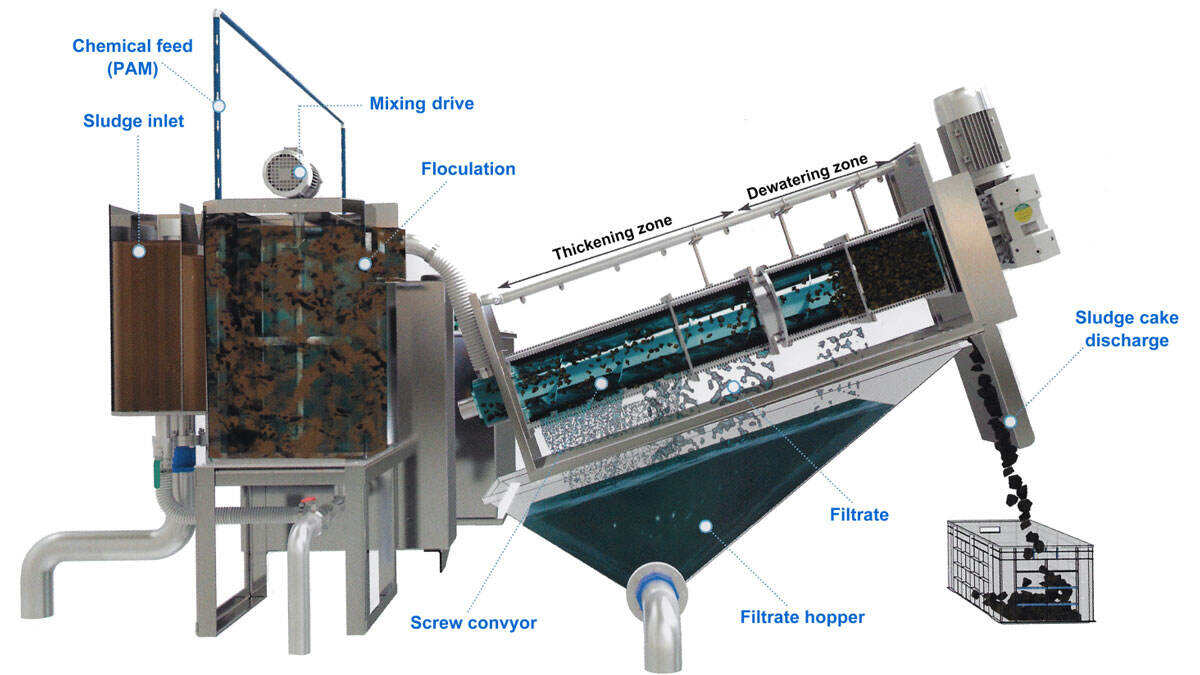

Working principle: The main body of the stacked screw dehydrator is a filtering device formed by stacking a fixed ring and a moving ring, and the screw shaft runs through it. The front section is the concentration section, and the back section is the dehydration section. The filter gap formed between the fixed ring and the moving ring and the pitch of the screw shaft gradually become smaller from the thickening part to the dehydrating part. While the rotation of the screw shaft pushes the sludge from the thickening part to the dehydration part, it also continuously drives the swimming ring to clean the filter joints to prevent clogging.

Working principle: The main body of the stacked screw dehydrator is a filtering device formed by stacking a fixed ring and a moving ring, and the screw shaft runs through it. The front section is the concentration section, and the back section is the dehydration section. The filter gap formed between the fixed ring and the moving ring and the pitch of the screw shaft gradually become smaller from the thickening part to the dehydrating part. While the rotation of the screw shaft pushes the sludge from the thickening part to the dehydration part, it also continuously drives the swimming ring to clean the filter joints to prevent clogging.

Modular design, different processing capacities can be customized according to requirements:

Due to its modular design and compact structure, the capacity of QY-SPD series screw press sludge dewatering machine can be easily expanded through parallel operation system to meet the treatment of various sludges with different capacities. The treatment capacity is 1.5 m3/h to 180m3/h at 0.2% sludge concentration and 0.3m3/h to 28m3/h at 2% sludge concentration.| Capacity | Sludge treatment capacity under different sludge concentrations(m3/h) | |||||

|---|---|---|---|---|---|---|

| Model | kg/h (DS) | 2000mg/l (0.2%) | 4000mg/l (0.4%) | 10000mg/l (1%) | 20000mg/l (2%) | 25000mg/l (2.5%) |

| QY-SPD-131 | 3-6 | 1.5 | 0.75 | 0.6 | 0.3 | 0.24 |

| QY-SPD-132 | 6-12 | 3 | 1.5 | 1.2 | 0.6 | 0.48 |

| QY-SPD-201 | 9-18 | 4.5 | 2.25 | 1.6 | 0.9 | 1.2 |

| QY-SPD-202 | 18-30 | 9 | 4.5 | 3.0 | 1.5 | 1.2 |

| QY-SPD-301 | 30-50 | 15 | 7.5 | 6 | 2.7 | 3 |

| QY-SPD-302 | 60-100 | 30 | 15 | 8 | 4 | 3 |

| QY-SPD-303 | 90-150 | 45 | 22 | 12 | 7 | 6 |

| QY-SPD-304 | 120-200 | 60 | 30 | 16 | 9 | 8 |

| QY-SPD-401 | 90-150 | 45 | 22 | 12 | 7 | 6 |

| QY-SPD-402 | 180-300 | 90 | 45 | 24 | 14 | 12 |

| QY-SPD-403 | 270-450 | 135 | 70 | 36 | 20 | 18 |

| QY-SPD-404 | 360-600 | 180 | 90 | 48 | 28 | 24 |

The BIO Series VOC treatment system combines adsorption + desorption + catalytic oxidation system to destroy 98% of benzene, esters,

The BIO Series GMP Adsorption System is engineered for Pharmaceutical VOC Adsorber, featuring "medical-grade carbon+hot N₂ regeneration" to achieve 99.5%

Fill out the form below, and we will be in touch shortly.