Since livestock and poultry manure contains organic matter and nutrients such as nitrogen, phosphorus, and potassium, after proper treatment, the solid part can be produced by composting and aerobic fermentation to produce organic fertilizer, and the liquid part can be used as liquid fertilizer. There are certain requirements for moisture content, and the livestock and poultry manure discharged from the farm is not only large in volume, but also has a high moisture content, which is difficult to transport, store and use directly. Therefore, a certain degree of dehydration treatment of livestock and poultry manure is a manure resource is important part of use.

The analysis of how to choose dehydration equipment for livestock and poultry manure is as follows.

1.Process flow of livestock and poultry manure treatment

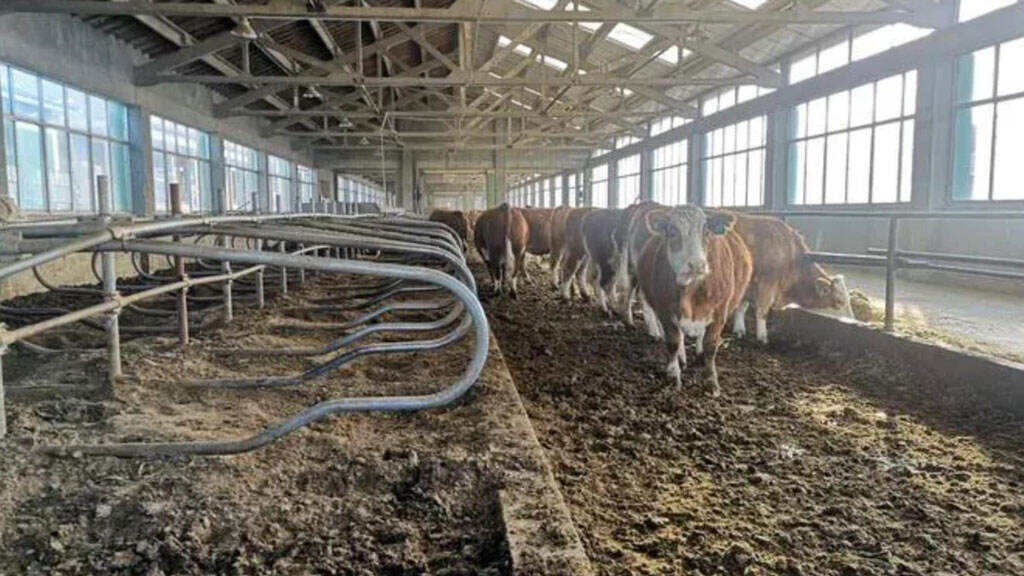

The moisture content of livestock and poultry manure varies according to the type and the way of manure cleaning. The water content of the rinsed manure is even higher.The moisture content of pig manure is 80-85%, cow manure is 83.20-86.36%, chicken manure is 50-75%.

The dehydration process of livestock and poultry manure is to flocculate and precipitate the manure with a moisture content of about 85% by flocculant and coagulant, and pump it to the screw press dewatering equipment with high pressure. The equipment consists of a gravity pressing area and a high-pressure pressing area. Since the fecal sewage after flocculation and sedimentation is easy to lose interstitial water, the first-stage dehydration is carried out in the gravity pressing area of the screw press dewatering equipment. With the continuous conveying and extrusion of the screw shaft, the pressure on the feces gradually increases, second dehydration is carried out. At the discharge end of the equipment, adjust the pressure in the equipment by adjusting the position of the back pressure plate to ensure that the moisture content of livestock and poultry manure discharged from the equipment is ≤ 45% to 55%, and the filtrate is discharged into the filtrate tank through the outlet of the equipment.

2.How to choose dehydration equipment for livestock and poultry manure

In the dehydration method of livestock and poultry manure, mechanical dehydration is more suitable for large-scale farms because of its convenient use, low energy consumption, and continuous operation. The mechanical dehydration equipment is divided into centrifugal dehydrator, screw press type, multi-rake bar screen, rotary drum screen and so on. Both the multi-rake bar screen and the rotary drum screen are solid-liquid separation methods of screening. The removal rate depends on the size of the sieve holes. The disadvantage is that the removal rate is low and the sieve holes are easily blocked. Centrifugal dewatering equipment is widely used in sludge treatment of chemical manufacturers, and screw press dewatering machine is a relatively advanced environmental protection sludge treatment equipment both at home and abroad, with low energy consumption, stable operation and low noise. The screw press dewatering machine selected and designed for the project is one of the screw press types, which has better dewatering effect in manure treatment and has great advantages in cost control and stability.

3.What should we care about when choosing a screw press sludge dewatering machine

-

The selection of motor and reduction mechanism is determined

The use of a good motor and reducer for the screw press dewatering machine is an important condition to ensure the stable operation and service life of the equipment.

-

The main part of the screw press dewatering machine

We need to know what material and process the equipment is made of for screw shafts, moving and fixed rings, filter cartridges, etc.

-

The whole processing technology of screw press sludge dewatering machine

We need to understand the component processing technology of the equipment, the welding technology and the surface treatment technology of the whole machine.

The above are some of the data we need to know before purchasing equipment, and then we can choose a suitable screw press dehydrator based on the handling capacity of livestock and poultry manure and other requirements in the farm.

Being a solid liquid separation solution provider, Bioetp is with rich experience in design and manufacturing the wastewater treatment machine. More important, Bioetp is able to provide overall solution for separation and conveying with the rich product line and strong fabrication and assembly capabilities.

Bioetp’s QY-SPD series Multi-Disc screw press is designed to handle handle various types of sludge in different capacities. The processing capacity is available from 1.5 m3/h to 180m3/h at 0.2% sludge concentration and 0.3m3/h to 28m3/h at 2% sludge concentration.

- Compared with the commonly used centrifugal dehydrator, it has low operating cost and low noise. The equipment adopts the spiral shaft variable diameter structure and the unequal pitch structure of the rotary vane, which has a better dewatering effect on poultry manure.

- Due to the use of a fully enclosed box, the emission of foul gas from poultry manure is effectively reduced, and environmental pollution is reduced.

- The equipment adopts a dynamic fixed ring structure, which can effectively prevent the blockage of the solidified material and has a self-cleaning function.