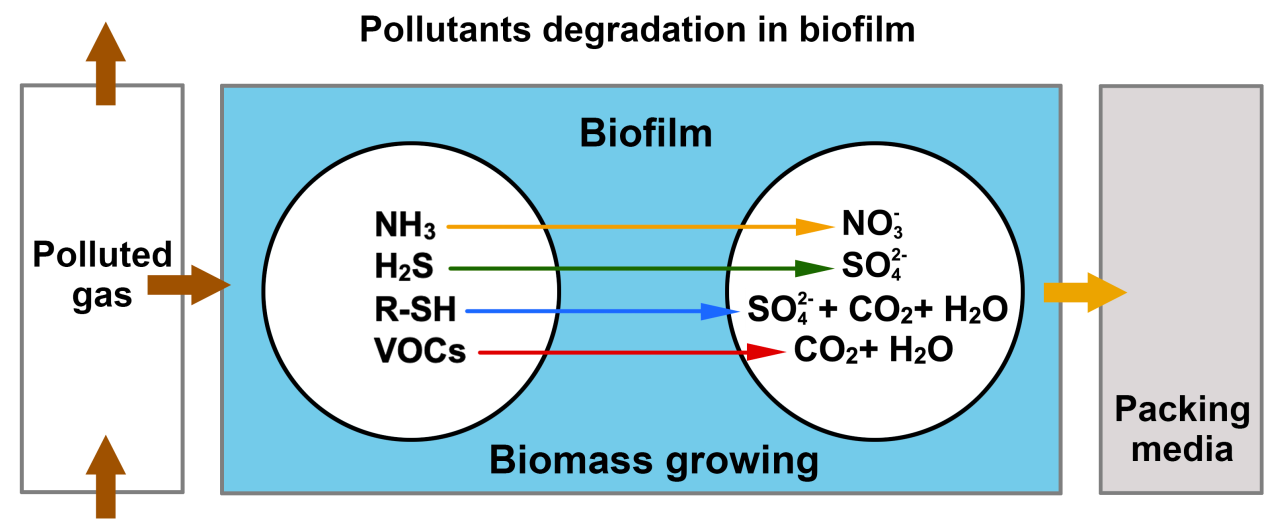

In a biofilter, the polluted gases pass through a bed of packing media covered with a layer of aerobic microorganisms. The pollutants are transferred from air into the biofilm where they are utilized by microbes as energy source. In the same time, the packing bed is continuously irrigated with an aqueous solution containing essential nutrients required by the bio-organisms.

In a biofilter, the polluted gases pass through a bed of packing media covered with a layer of aerobic microorganisms. The pollutants are transferred from air into the biofilm where they are utilized by microbes as energy source. In the same time, the packing bed is continuously irrigated with an aqueous solution containing essential nutrients required by the bio-organisms.

| Exhaust gas condenser | The condenser turns most of the water vapor in the exhaust gas into liquid water, which can reduce the volume of the exhaust gas by more than 40% and reduce the subsequent processing load. |

|---|---|

| Chemical Spray Tower | The spray scrubber absorbs ammonia and hydrogen sulfide in the exhaust gas by adding different absorption liquids, reducing the load of biological trickling filtration. |

| Biofiltration | Using VOCs in exhaust gas as the energy and carbon source of microorganisms, through the metabolism of microorganisms, degrade trimethylamine, ethanethiol, ammonia, hydrogen sulfide and other substances in exhaust gas into non-toxic and harmless CO2H2O, sulfate, nitrate, etc. of small molecules. |

| Deodorization costs are lower | Friendly to the environment | No secondary pollution | Higher deodorization efficiency |

Through biological filtration technology, the pollutants in the exhaust gas are degraded by aerobic bacteria into CO2, H2O, sulfate, nitrate and other stable products

Advantages of biological filtration: Compared with other deodorization technologies, biological filtration costs less, is more environmentally friendly, does not produce secondary pollution, and has higher removal efficiency.

The BIO Series VOC treatment system combines adsorption + desorption + catalytic oxidation system to destroy 98% of benzene, esters,

The BIO Series GMP Adsorption System is engineered for Pharmaceutical VOC Adsorber, featuring "medical-grade carbon+hot N₂ regeneration" to achieve 99.5%

Fill out the form below, and we will be in touch shortly.